Coordinating beneficiary, expert in laboratory and full-scale investigation of bioprocesses in wastewater treatment. Responsible for scientific dissemination and networking with other projects, and for the project environmental impact assessment.

Project n. LIFE16 ENV/IT/000486

End date: March 31 > November 30, 2021

EU Contribution: € 760.624

Innovative wireless tool for reducing energy consumption and GHGs emission of water resource recovery facilities

Roles

UNIFI

Italy

UGent

Belgium

Associated beneficiary, expert in bioprocess modeling and developer of the protocol. Collaborator in scientific dissemination and responsible for networking in north-Europe.

CUOIODEPUR

Italy

Associated beneficiary, manager of the test WRRF for prototype testing. Responsible for the experimental activity on the test plant and for networking with industrial sector.

UTILITATIS

Italy

Associated beneficiary, responsible for surveys and main dissemination on Italian territory. Responsible for the socio-economic impact assessment and for networking with Italian water boards. It is also responsible for the communication activities.

WEST SYSTEMS

Italy

Associated beneficiary, expert in automation and control, prototype developer. Responsible for design and realization of the prototype and for the marketing aspects. It is also responsible for networking and dissemination with related companies in the technology provider field.

The context

Aerobic activated sludge processes are the most used technology for wastewater treatment. Therefore, the optimization of the oxygen transfer process can significantly reduce energy costs and carbon footprint (CFP).

The main barrier in implementing control strategies for maximizing the efficiency of aeration systems is the lack of insights regarding oxygen transfer process, efficiency and potential savings in terms of energy and greenhouse gases (GHGs) emitted.

The efficiency of the aeration systems depends both on the efficiency of its components and on site-specific characteristics which are all dynamic phenomena making predictions inaccurate. Hence, a proper on-site monitoring of the oxygen transfer efficiency and of the direct and indirect GHGs production in WRRFs is essential for assessing the best aeration process management for energy consumption and carbon footprint minimization.

Objectives

This tool is composed of an instrument (LESSDRONE) for monitoring the oxygen transfer efficiency (OTE) in operating conditions and a user-friendly protocol for converting complex process information in actions aimed at minimizing WRRFs CFP and energy demand.

The reduction of energy costs and the minimization of GHGs emissions, complying with the quality effluent limits, will improve the environmental and economic sustainability of WRRFs while reducing associated costs for citizens and industries.

The applicability and the suitability of the innovative tool will represent a crucial issue of the project in order to ensure the transferability to other WRRFs also operating in different contexts and industrial sectors.

The innovative technology

The technology used for the OTE measurement is the off-gas method which is based on a gas phase mass balance between the oxygen content of the inlet gas and the off-gas.

LESSDRONE wants to take the concept of off-gas testing a step ahead by demonstrating that it is nowadays possible to produce an innovative technology providing more information than with conventional off-gas testing instruments on the biological process investigated, gathering important clues on the production of GHGs and developing sensible WRRF CFP reduction strategies.

LESSDRONE will be equipped with new instrumentation enlarging the spectrum of monitored variables to GHGs monitoring. All the instrumentation will be on board, limiting the dimension of the floating hood to ensure manoeuvrability and facilitating automation. With LESSDRONE space requirements are reduced by merging the hood and the analyser in a unique device.

The automated character of LESSDRONE will make possible to fully monitor all areas of the tank, to reduce personnel requirements and to monitor the OTE and the GHGs production also when the plant is closed. The innovative technology foresees the implementation of a protocol, a model based user-friendly tool, which integrates data from the LESSDRONE, processes information and external inputs, and translates these in applicable actions aimed at minimizing CFP footprint.

The tool will be applicable to all WRRFs using biological processes equipped with diffused aeration systems.

The strategy

The size of the plant is significant from both organic load and influent flow point of view.

The innovative tool will be implemented and optimized during the project activity in 3 Italian WRRFs (S.Colombano, Tuscany; Sestri Ponente, Liguria and Roma est, Lazio) and 2 north European WRRFs (Eindhoven and Tillburg, The Netherland), covering a range of wastewater treatment technologies as wide as possible, in order to realize a protocol easily applicable to a wide range of technologies and environments.

The protocol optimization in different WRRFs around Europe will ensure the transferability of the technology.

Project results will be disseminated to various other fields of application, such as petrochemical, textile, paper industry, agro-food, etc. where highly loaded streams are generated. All these industrial activities will significantly benefit from a more efficient use of energy in wastewater treatment and will foster European competitiveness in the global market.

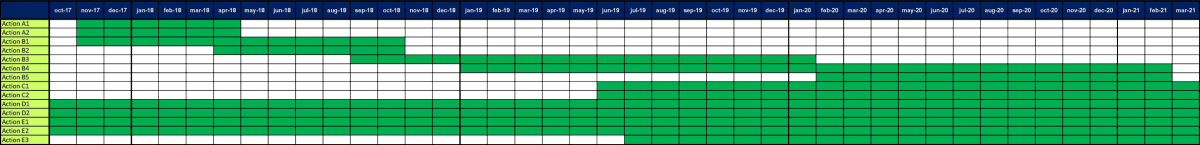

Actions and time schedule

A. Preparatory actions

A1. Test WRRF characterization

A2. Survey on Italian, Belgian and Dutch WRRFs

B. Implementation actions

B1. Design, construction and refinement of LESSDRONE prototype

B2. Testing of LESSDRONE

B3. Procedure development for off-gas monitoring with LESSDRONE

B4. Protocol development for reducing energy consumption and GHGs emission

B5. Application of the protocol in selected WRRFs

C. Monitoring of the impact of the project actions

C1. Technical and environmental impact assessment of the project

C2. Socio-economic impact of the project

D. Public awareness and dissemination of results

D1. Dissemination planning and execution

D2. Networking

E. Project management

E1. Project management

E2. Indicators and Project monitoring

E3. After Life Plan